A global shift in engineering accountability is forcing asset owners to rethink how design validation protects people, assets, and decisions.

HOUSTON, TX, UNITED STATES, January 26, 2026 /EINPresswire.com/ — Across the global industrial landscape, a quiet but significant shift is underway. Engineering decisions that were once considered purely technical are now carrying personal, financial, and legal consequences for those who approve them. In 2026, asset owners, plant managers, and senior engineers are rethinking how design validation is approached, not because engineering codes have changed, but because accountability has.

Industrial facilities worldwide are operating under mounting pressure. Ageing assets are being pushed beyond their original design life, capital expenditure decisions are delayed, and operating conditions are far more dynamic than what legacy design documents ever assumed. At the same time, regulatory scrutiny has intensified, insurance requirements have tightened, and post-incident investigations have become far more rigorous.

What has changed most, however, is who bears the risk.

Today, a design that meets code is no longer automatically considered safe, acceptable, or defensible. Regulators, insurers, and third-party reviewers are no longer satisfied with checklists or summary calculations.

They are asking deeper questions:

1. Why was this method chosen?

2. What assumptions were made?

3. What happens if those assumptions fail?

4. And most importantly, can this engineering decision withstand scrutiny?

For many asset owners, this shift has exposed a critical vulnerability. Traditional validation approaches, including hand calculations and black-box simulations, often fail to explain how loads truly travel through equipment, how local stresses interact, or how real operating transients affect long-term integrity. When an incident occurs, engineering reports are no longer reviewed only by engineers. They are examined by auditors, insurers, regulators, and legal teams, each looking for clarity, traceability, and defensibility.

In response, design validation is evolving from a compliance exercise into a risk-management discipline.

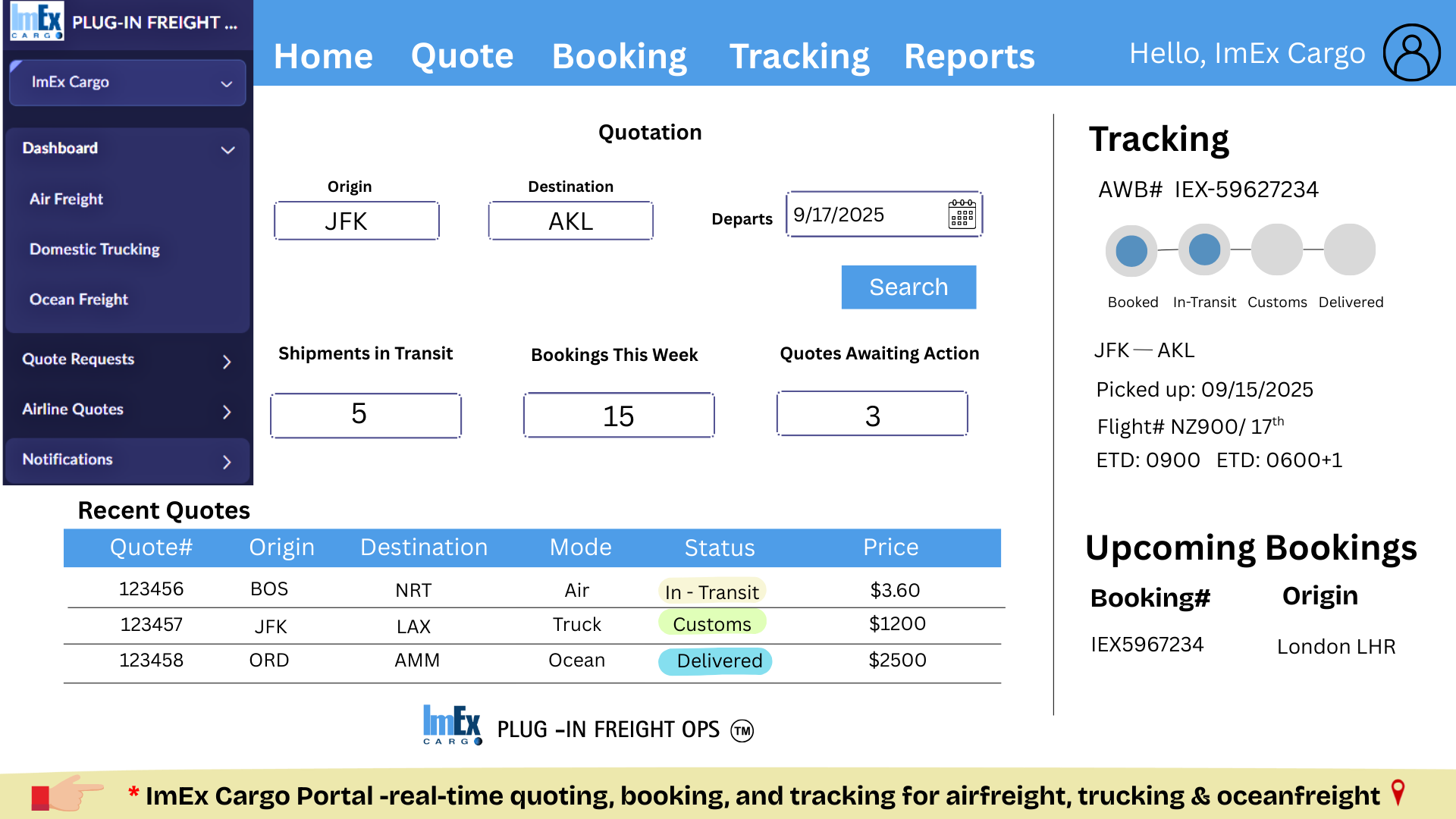

Independent engineering validation is increasingly being used not as a formality, but as a strategic safeguard. Asset owners are seeking analyses that go beyond numerical results, studies that clearly document assumptions, justify modelling choices, and explain failure envelopes in plain engineering logic. The objective is no longer just to demonstrate adequacy, but to reduce ambiguity and personal exposure for decision-makers through independent design validation.

This growing demand for accountability has also elevated the role of internationally recognized professional sign-offs. Independent reviews carried out under IntPE oversight are increasingly relied upon to provide engineering sign-offs that withstand audits, regulatory reviews, and third-party scrutiny. For asset owners, such validation offers confidence that critical decisions are supported by defensible engineering judgement rather than unchecked assumptions.

This shift is especially visible in high-risk sectors such as oil and gas, petrochemicals, power generation, chemicals, and heavy manufacturing. In these industries, even minor failures can lead to extended shutdowns, environmental consequences, or long-term reputational damage. As a result, senior engineers and managers are becoming increasingly cautious about what they sign off on.

Another factor driving this change is the growing gap between original design intent and present-day operation. Many plants today experience frequent start-stop cycles, load fluctuations, emergency shutdowns, and process upsets that were never considered in original designs. Fatigue, thermal transients, and local stress concentrations have emerged as dominant failure mechanisms, often invisible until it is too late.

Globally, engineering leaders are responding by redefining what good engineering means in 2026. It is no longer about producing thicker reports or more colourful plots. It is about delivering engineering opinions that can withstand audits, peer reviews, and post-incident scrutiny, without relying on undocumented assumptions or unexplained simplifications.

About Ideametrics Global Engineering

Ideametrics Global Engineering is an independent engineering consulting firm specializing in advanced simulation, mechanical integrity assessment, and code-compliant validation for critical industrial assets. The company works with asset owners, EPCs, and operators across high-risk industries to support technically defensible engineering decisions under real-world operating conditions.

Pandhari Sanap

Ideametrics

+1 307-243-4045

email us here

Visit us on social media:

LinkedIn

Legal Disclaimer:

EIN Presswire provides this news content “as is” without warranty of any kind. We do not accept any responsibility or liability

for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this

article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

![]()